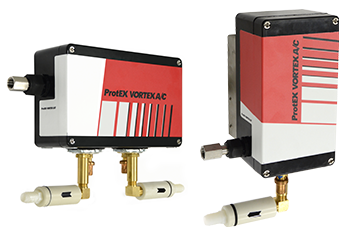

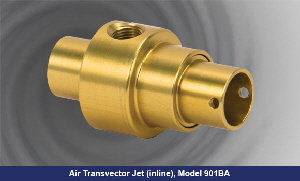

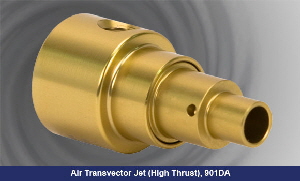

PRODUCTS

C.C. Steven, your ANSWER to compressed air challenges.

We specialize in producing innovative answers for your most difficult challenges that require compressed air products, by utilizing the industries’ top manufacturers in their fields.

More importantly, a live applications engineer is available to assist you in your application if you contact us M – F 8:00am – 5:00pm (GMT-08:00) Pacific Time (US & Canada) at (805) 658-0207 or email: static@ccsteven.com